The diaphragm cryocooler, from need to invention to commercialisation

A brief(ish) history.

By Alan Caughley 8/7/25

The story of this machine starts with a company called American Superconductor (AMSC), who were making the first generation of high temperature superconducting (HTS) wire. They quickly realised that to have a market for their wire, the applications would need constant cooling to liquid nitrogen temperatures and below. Liquid nitrogen was readily available for cooling, but reliance on trucked supplies for the likes of a high voltage power cable or transformer feeding a city was not practical and that a new breed of cryogenic refrigerators would need to be made. Something was required of a size between the huge liquid nitrogen plant size and the tiny military or space cooler size, and something that was more robust than something that would be used in a lab or spacecraft.

Alan Caughley, a mechanical research engineer at Industrial Research Ltd (IRL) was recruited into IRL’s superconductivity team to look at the problem of making an industrialised cryocooler in the ‘mid-range’ of 500-2kW of refrigeration at approximately 50-70 Kelvin (-220C to -200C).

Alan’s started off looking at the incumbent technologies from the lens of the industrial mid-range cooling requirements. State of the art at the time was either: crank-piston based Stirling refrigerators descended from the original Philips Stirling programme of the 1950’s which had a very high maintenance requirement; or Gifford McMahon coolers that were commonly used for cooling labs machine but not suited to the outdoors; or the small space coolers, which were efficient and long-lasting but were very expensive to make. It was also a time when a new cold-head technology, the pulse tube. was starting to mature. Pulse tubes, sometimes called acoustic Stirling, use a resonant plug of gas in the ‘pulse tube’ instead of the expansion piston of a Stirling cycle. The pulse tube is very attractive as it has no moving parts in the cold part of the cryocooler, leading to no wear or need for ultra-high accuracy clearance gap seals. The trick with the pulse tube is to get the mass flow in the pulse tube moving smoothly and at the right time to get refrigeration. Pulse tubes also need a pressure wave generator (PWG). Small pulse tubes (~1 W at 80K) use linear motor PWGs, which work very well but become difficult to make and operate at large scales due to the amount of energy contained in the resonance and the need for clearance gap seals.

The conclusion was that Pulse Tubes offered the most promise but needed a different pressure wave generator. AMSC had a previous pulse tube development programme which had produced a pulse tube that was given to IRL for development. This defined the size of the PWG. Pistons, and piston sealing were the problems with large PWGs, so Alan investigated bellows and diaphragm seals. Pulse Tube cryocoolers use helium gas at approximately 25 bar (1 bar ~1 atmosphere) average pressure and need a 5 bar pressure wave. Bellows don’t like high pressures, so it was down to diaphragms. Alan optimised a metal diaphragm geometry for the conditions. The other problem was that high pressure, and a large diaphragm diameter means a very large (tonnes) average force on the diaphragm, a force that needs to be balanced or held back by the mechanism. The solution was a second diaphragm, at the same average pressure, pushing the other way. The driving mechanism could be a lubricated crank in between as the diaphragms sealed in the ultra-clean working gas. The first prototype machine, Figure 1, was built to prove the concept, driving a pulse tube to below 80 K.

Figure 1:The first diaphragm PWG with the AMSC pulse tube, in air producing a frost ball.

Figure 1:The first diaphragm PWG with the AMSC pulse tube, in air producing a frost ball.

The crank mechanism however, did not last very long and showed that the diaphragm forces were too high to be practical is a straight crank.

The initial funding was IRL internal money, and when the proof of concept was looking good then some government ‘transition’ funding was secured. This allowed a bid for a full programme to be submitted which was successful.A new pressure wave generator was designed incorporating a lever/crank mechanism and a larger displacement, 200cc, Figure 2. Two of these machines were built, one stayed in Christchurch and the other went to Cryomech in the USA for their pulse tube development. Cryomech developed a pulse tube using the PWG that achieved 108 W of cooling at 77 K with 3.7 kW power input[1].

Figure 2: The MK2 PWG in testing for shipping to the USA in 2007. It is coupled to the AMSC a pulse tube with a flexible hose. On the wall behind you can see two diaphragms, the original MK1 diaphragm and the new MK2, 200cc, diaphragm.

Figure 2: The MK2 PWG in testing for shipping to the USA in 2007. It is coupled to the AMSC a pulse tube with a flexible hose. On the wall behind you can see two diaphragms, the original MK1 diaphragm and the new MK2, 200cc, diaphragm.

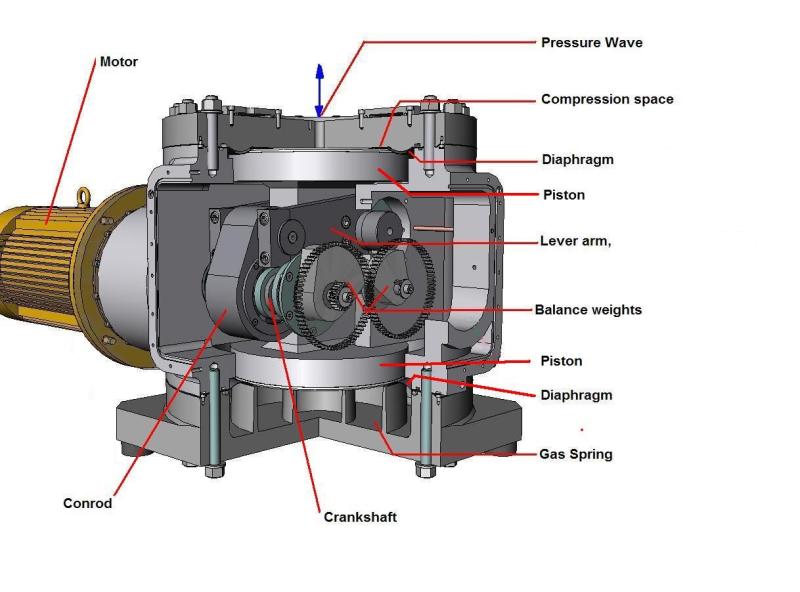

A tidy version of the MK2 PWG was made with a cast crank case and improvements in the mechanism, Figure 3, this machine spent 6 months at Cryomech to complete their development and was on their pulse tube at the 2008 Cryogenic Engineering Conference as the debut of the diaphragm PWG, then it went to France for a team at Air Liquid to assess. The Air Liquide team liked the machine and wanted a little more volume displacement, so we built them four machines in the end with 240cc of displacement, pushing the diaphragm stress to the limit, and resulted in a very successful demonstrator for a CO2 scrubber, with 600 W at 120 K from each pulse tube Figure 4. The original MK2 PWG went to Wellington for two years for experimental work on gas spring modelling at HTS-110, then back to Christchurch where it was the workhorse for a diaphragm based Stirling cryocooler and another pulse tube cryocooler development.

Figure 3: Internal workings of the diaphragm PWG showing the lever mechanism.

Figure 3: Internal workings of the diaphragm PWG showing the lever mechanism.

Figure 4: Three pulse tube cryocoolers at Air Liquide in France, 2009

Figure 4: Three pulse tube cryocoolers at Air Liquide in France, 2009

The next challenge was scaling, how to make larger and smaller PWGs. 1000cc displacement was nominally chosen for the large size. Doing the calculations it became obvious that the lever mechanism didn’t have enough leverage to work, the bearings would have to be too big. A hydraulic lifter mechanism was developed that gave a large leverage ratio in a very compact space, this allowed the 1000cc machine to be designed and built. The hydraulic lever was also used to go as small as practical for the diaphragm, with 20cc of displacement, Figure 5. Both these machines were built and tested. A 60cc PWG and 80W pulse tube were developed in response to a customer enquiry for oxygen liquefaction, which was followed by a 100 W pulse tube with a 90cc PWG for another customer. This time it was coupled with the rest of the balance of plant for a nitrogen liquefier in partnership with a US company called Kelvin International.

Figure 5A: The 20cc PWG with a 10 W at 77 K pulse tube.

Figure 5A: The 20cc PWG with a 10 W at 77 K pulse tube. Figure 5B: The 20cc PWG with a 10 W at 77 K pulse tube.

Figure 5B: The 20cc PWG with a 10 W at 77 K pulse tube.

Figure 6: 100 W pulse tube (upper left) in the nitrogen liquefier

Figure 6: 100 W pulse tube (upper left) in the nitrogen liquefier

HTS110, a superconducting magnet manufacturer and spinoff from the IRL superconductivity team, was the first commercial partner for the cryogenic refrigeration programme. HTS110 were bought by Scott Technology, who were able to contribute a considerable amount of valuable machine building and electrical skills to the liquefier, Figure 6. Eventually, Scott Technology decided that cryocooler manufacturing was too big a distraction for a superconducting magnet manufacturer and withdrew HTS110 from the refrigeration programme.

Fortunately, Fabrum Solutions, a Christchurch manufacturer of composites and components for the cryogenics industry was growing steadily and working with a French company, Absolut System, who were a spinoff from Air Liquide, and comprised the pulse tube development team. Fabrum saw the cryocoolers as complementary to their composite cryostat and manufacturing business and licensed the cryocooler technology. They joined with Absolut System to form AF Cryo. They decided that the ideal size of cryocooler for the diaphragm technology was a 500 W at 77 K pulse tube with a 330cc PWG drawing about 10 kW of electricity. The IRL team designed the PWG and it was coupled to a pulse tube designed by Absolut System and built by Fabrum. The resulting cryocooler performed to specification, and three of the same pulse tubes were be mounted on the 1000cc PWG for 1500W at 77K.

The cryocoolers worked very well as nitrogen liquefiers. Fabrum collaborated with a local gas supplier, Southern Gas, and installed a PTC330 then a PTC1000 liquefier for testing in a real environment, Figure 7. These were wild times where the lab machines made it to real applications, there were failures of components, rapid fixes and process improvements. In the end we were able to report on a year of operation of the PTC1000 in an industrial setting, complete with dust, dirt, ambient temperature swings and customers needing product [2].

With IRL being restructured to create Callaghan Innovation, the long-term funding for the research programme ran out and was not renewed. This hastened the transfer of the technology, including machines and some staff, to Fabrum. Fabrum have since developed the technology further, refined and integrated the cryocoolers into nitrogen, oxygen and air liquefaction and eventually used it as a key refrigeration stage for hydrogen liquefiers.

The story carries on with Fabrum.

Figure 7: The 1000cc PWG with three pulse tubes, producing 1500W at 77K working as a Nitrogen liquefier at Southern Gas for a year.

Figure 7: The 1000cc PWG with three pulse tubes, producing 1500W at 77K working as a Nitrogen liquefier at Southern Gas for a year.

Figure 8: The cryogenic refrigeration team. Back row from left: Michael Nation, Alan Caughley, Nick Emery. Front row from left: Nathan Allpress, Theunis Klok, Jonas Meier, Neil Glasson. Alan is sitting on the 1000cc PWG crankcase and the cryocooler on the stand is called the NE100, nominally 100W at 77K with a 90cc PWG.

Figure 8: The cryogenic refrigeration team. Back row from left: Michael Nation, Alan Caughley, Nick Emery. Front row from left: Nathan Allpress, Theunis Klok, Jonas Meier, Neil Glasson. Alan is sitting on the 1000cc PWG crankcase and the cryocooler on the stand is called the NE100, nominally 100W at 77K with a 90cc PWG.

Glossary:

Technical:

K, degrees Kelvin, temperature scale where 0 is absolute zero and 273.13K is water ice, the scale is the same as the Celsius scale.

Cryogenics: refers to below 150 K in temperature, and the temperatures where the permanent gases (methane, oxygen, Argon, Nitrogen, Neon, Hydrogen and Helium) liquefy then solidify.

Refrigerator: a device that absorbs heat in a cold environment and rejects it in a warm environment. Sounds simple and ideal for cooling your drinks, but as the temperature difference gets bigger it gets harder. It is very much like lifting water out of a well. A shallow well can have a big bucket and lift a lot of water easily. Cryogenics is like a very deep well where the winch (the refrigerator) is huge, the bucket is small and what is more it is dry at the bottom and raining at the top. The winch does a lot of work for not much gain.

Cold head – the part of a cryogenic refrigerator that lifts heat from a cryogenically cold environment to ambient temperatures. It usually looks like a cylinder with one end being copper and very cold, the other end gets hot.

Stirling refrigerator – a refrigerator that runs on a gas cycle (no condensation or boiling as in a conventional refrigerator). Stirling refrigerators have a compression piston that produces a pressure wave and an expansion piston or a displacer, timed to expand the gas when most of it is in the cold part of the machine (and therefore absorbs heat) , and move the gas back to the warm part when it is compressed and rejects heat. In between the cold and warm parts of the machine, the gas flows through a regenerator which is a porous section that cools the gas on the trip to the cold part of the machine and warms it up on return. The Stirling cycle is an ideal cycle and practically Stirling refrigerators are the most efficient refrigerators in the 50-150 K temperature range. Unfortunately, Stirling machines use pistons in the cold part of the machine, and the temperatures they operate mean lubricants are not an option, leading to short life through wear or high expense from maintaining non-contact clearance seals.

PT, Pulse tube- The pulse tube refrigerator is a variation of a Stirling refrigerator that uses a moving plug of gas in the pulse tube instead of the expansion piston. This removes the cold expansion piston from the Stirling cycle enabling a simpler, cheaper and long-life cold head.

Gifford-McMahon refrigerator – a cryogenic refrigerator that operates using a modified air conditioning compressor, filters to remove residual oil in the gas and a valve set to produce a pressure wave for the cold head. The cold head has a displacer and regenerator

PWG, Pressure wave generator- traditionally a piston in a cylinder that creates a pressure wave for driving a Stirling or Pulse Tube refrigerator cold head

Diaphragm- a flexible membrane that moves as an alternative to piston and cylinder for volume changes - sealing and wear advantages.

HTS – High Temperature Superconductors. ‘High Temperature’ means higher than the liquid helium temperatures (4 K) needed for low temperature superconductors. HTS usually operates around liquid nitrogen temperatures (77 K) and below. HTS wires carry electrical current without resistance and can carry much more electricity than their equivalent sized copper wire allowing more compact and lighter machines and higher magnetic fields.

Players:

Fabrum- A New Zealand manufacturing company, based in Christchurch, who started out making composites (sophisticated fibre glass and carbon fibre), got into cryogenic composites and components and now is manufacturing cryogenic systems including cryogenic refrigeration, liquefaction and storage. Fabrum | Liquid Hydrogen Systems

AMSC - American Superconductor: An American company that started out making the first generation of HTS wires American Superconductor (AMSC) and has branched out into other power electronic fields.

IRL, Industrial Research Ltd- a New Zealand Crown Research Institute. Performed directed research for government and industry until being merged to form Callaghan Innovation. 1991-2013

Callaghan Innovation- a New Zealand Government Agency, was formed as a merger of a science and engineering research institute (IRL) and government functions that administered research funding for industry. Disestablished in a science reform in 2025. 2013-2026

HTS110 - A New Zealand manufacturing company based in Lower Hutt that makes high power magnets and custom superconducting coils. A spinoff from IRL’s superconducting team. HTS110

Scott Technology – A New Zealand manufacturing company based in Dunedin that makes automation systems. Scott Technolgy

Air Liquide – A French multinational gas company that supplies gases and cryogenics to many industries. Air Liquide

Absolut System – a French cryogenic engineering company - Absolut System

CryoMech (now called Bluefors) – A US firm that makes Gifford McMahon refrigerators., the company was started by the inventor of the Gifford McMahon refrigerator. Bluefors Syracuse

Kelvin International corporation– a US firm that makes nitrogen liquefiers. Kelvin International, Inc. - Excellence in Cryogenics